They are used for precise coordinate boring, drilling, milling and thread cutting. They are particularly suitable for processing box, plate and spatially broken workpieces made of cast iron, cast steel, steel and other materials that can be machined, especially for workpieces of large and maximum dimensions and weights.

Introducing the

WRD 13

The horizontal plate boring machine with extending ram and main spindle marked WRD 13 is based on the original generation of WHN 13 CNC horizontal milling and boring machines produced by TOS VARNSDORF a.s. The machine headstock and column is identical to the WHR 13 machine. The drive of the machine in the X axis is solved by the Master & Slave system. Three linear guides in the X axis provide the machine with perfect machining precision and a high feed speed of up to 21,000 mm/min.

Introducing the

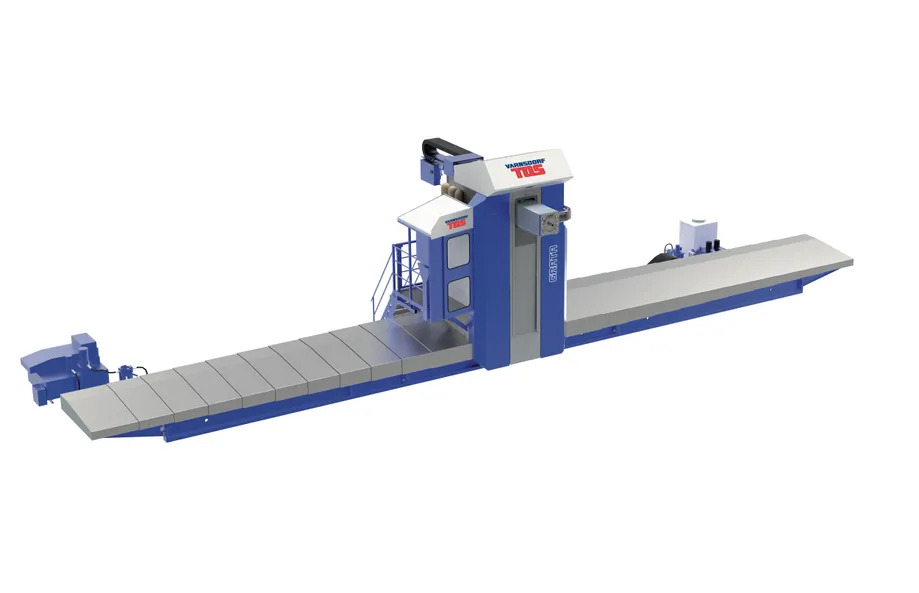

GRATA

Floor-type machine tools GRATA are designed for precise and highly-productive milling, drilling, reaming and threading. They are particularly suitable for processing box, plate and spatially broken workpieces made of cast iron, steel and other materials that can be machined, especially for workpieces of large dimensions and weights. The machines are equipped with an extending ram, which can be equipped with any of a wide range of additional technological devices that greatly expand the possibilities of machine use.

The machines are intended for serial production and for complex technological use. They are continuously controlled in the three basic coordinates (X, Y, Z), or other axes depending on the special accessories used, in position feedback from the machine control system.

Introducing the

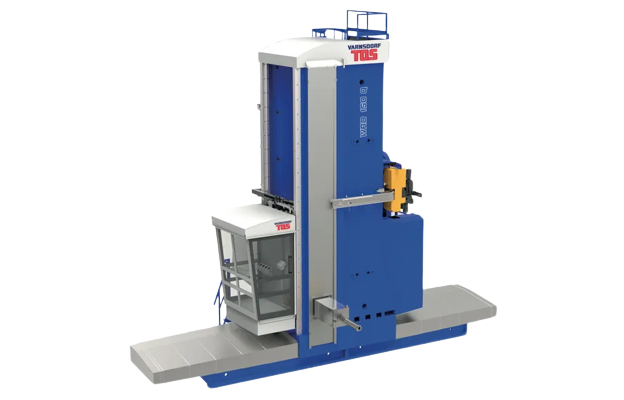

WRD 130/150/160

Boring machines WRD 130/150/160 are characterised by modern construction technology and high levels of performance parameters. They can be supplemented with a number of technological devices, which can greatly extend the technological capabilities of the machine.

The machines are designed for precise and highly productive coordinate drilling, boring, milling and thread cutting, especially into large and heavy workpieces or shaped workpieces from cast iron, cast steel and steel.

Depending on the technological requirements, the machines can be supplemented with a clamping array made up of clamping plates or one or more additional tables.

Introducing the

WRD 170/200

WRD 170/200 is the largest and heaviest representative of floor-type machines with a linear guide from the production portfolio of TOS VARNSDORF a.s. You may use the machine for accurate coordinate boring, drilling, milling and thread cutting.

WRD 170/200 is suitable for processing box-type, plate-type and shaped workpieces from cast iron, cast steel, steel and other materials that can be machined, especially for workpieces of large and maximum dimensions up to weights of 150 tonnes.

The machines can be supplemented with a number of additional technological devices, which greatly expand the flexibility of the machine.

Introducing the

WRD 160/180/200 H

The largest, heaviest and most powerful, this is representative of the fully hydrostatic machines of the series WRD 160/180/200 H. Due to the excellent properties of hydrostatic guidance, the machines are designed for the most demanding machining methods.

The machines WRD 160/180/200 H are designed for the most precise coordinate boring, drilling, milling and thread cutting. They are particularly suitable for processing box-type, plate-type and shaped workpieces from cast iron, cast steel, steel and other materials that can be machined, especially for workpieces of large and maximum dimensions up to weights of 200 tonnes.